charpy impact test grinding|charpy impact test calculation table : advice The Charpy test is most commonly used to evaluate the relative toughness or impact toughness of materials and as such is often used in quality control applications where it is a fast and economical test. It is used more as a . WEBsite Traffic Estimator [Update]. Enter the URL of any website and find out how many people visit this site every month. In addition the site Traffic Checker shows you how many pages an average user views .

{plog:ftitle_list}

Resultado da 11 de nov. de 2022 · Para iniciar nossa lista com apps que possibilitam como clonar o celular do marido a distância não poderíamos escolher outro .

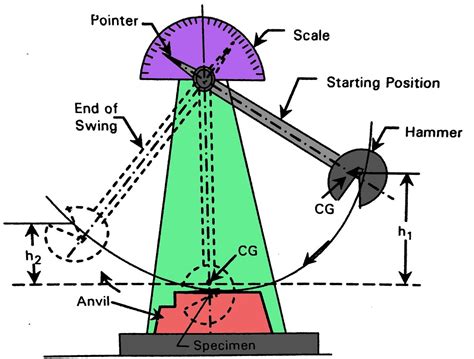

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The Charpy test is most commonly used to evaluate the relative toughness or impact toughness of materials and as such is often used in quality control applications where it is a fast and economical test. It is used more as a .The widely used Charpy impact test is a standard way to assess toughness quantitatively in notched specimens. In this test a standard bar specimen, with a square cross section and a V .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .

Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle . Semantic Scholar extracted view of "Estimation of fracture toughness K IC from Charpy impact test data in T-welded connections repaired by grinding and wet welding" by G. Terán et al. Skip to search form Skip to main content Skip to account menu. Semantic Scholar's Logo. Search 221,093,637 papers from all fields of science .

The Charpy impact test was conducted to examine the influence of salt spray. The impact strength CVN show decreasing trend with increase in exposure hours. . Estimation of fracture toughness KIC from Charpy impact test data in T-welded connections repaired by grinding and wet welding. Eng. Fract. Mech., 153 (2016), pp. 351-359. View PDF View . This work presents, for the first time, and estimation of fracture toughness K IC correlations from Charpy V-notch (CVN) impact test data extracted from T-welded connections repaired with rectangular grinding and filled by wet welding. To obtain K IC values, equations based on the yield stress (σ YS) of the wet welding beads were used.The estimated K IC data . A Rockwell hardness test was done to measure the hardness of the alloy steel samples, and a Charpy impact test were conducted to measure the impact toughness of the samples. The results showed the microstructures of the as-quenched and as-tempered samples consist of martensite with different orientation and small inclusions of irregular shapes .

The Charpy impact test is commonly used to assess plastics' toughness and impact resistance. It involves subjecting a standardized specimen to the impact of a swinging pendulum, causing a fracture. By measuring the amount of energy absorbed during fracture, the test provides valuable insights into the material's ability to withstand sudden .The Charpy V-notch impact test is performed by machining ‘V’ notch in the centre of the standard test specimen and the test specimen is fractured at a test temperature by a swinging pendulum of a known potential energy. The test specimen absorbs portion of the energy to fracture and this absorbed energy is indicated by the machine.Plastic V notch impact sample 80*10*4mm Organic glass V notch impact sample 80*10*4mm . By testing plastics with the Charpy test method the impact resistance of the plastic can be determined. Charpy impact testing can also be used to determine the sensitivity of notched plastics specimens. Impact resistance of plastic notched specimens measures .

This work presents, for the first time, and estimation of fracture toughness KIC correlations from Charpy V-notch (CVN) impact test data extracted from T-welded connections repaired with .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

A Charpy impact test (CVN test) is used to measure the fragile-ductile temperature and as a quality control test. This evaluation's simplicity allows converting energy values to fracture toughness .The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be . Comparing the mechanical properties of Ti-652 titanium alloy with 9 kinds of microstructure, M9 was found to have the highest impact toughness (53.713 J/cm 2) which features a duplex microstructure and underwent more severe plastic deformation during the test of samples, leaving shear bands and “ripple-like” patterns on the quasi-static . This paper presents results of fracture toughness and Charpy impact tests of 4 steels prepared by metal injection moulding (MIM) method: AISI 4140, 4605, 17-4 PH and SS 420W Grade. Charpy impact testing was performed on the series of machined specimens with sub-size cross-section to obtain values of CVN impact energy. Fracture toughness test .

the effect of fatigue precracking versus vnotching on impact testing of charpy specimens. 120: precracking and strain rate effects on hslaio0 steel charpy specimens. 134: significance of precracking variables for slowbend charpy tests. 142: specimen size effects in .The Class D Metals Impact Tester is a Single column impact testing system designed for Charpy Impact testing according to ASTM E23, ISO 148 and EN10045 industry standards. The Class D has has two popular models with . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

size), Bauschinger, Le Chatelier and Charpy (impact test). Georges Augustin Albert Charpy, a French-man, was born in 1865 and graduated from the École Polytechnique in 1887 with an engineering degree majoring in marine artillery. He went on to become a metallurgi-cal engineer and later a professor. Charpy became interested in measuring the impact The influence of strength mismatch in a dissimilar steel joint on the Charpy absorbed energy was numerically analyzed on the basis of the Beremin model. The toughness correction ratio γCVN was defined as the ratio of the Charpy absorbed energy of a dissimilar steel joint specimen to that of a homogeneous specimen under the same Weibull stress. The . This paper presents results of fracture toughness and Charpy impact tests of 4 steels prepared by metal injection moulding (MIM) method: AISI 4140, 4605, 17-4 PH and SS 420W Grade.

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch. Class G – Servo-Motor Single Column Charpy/Izod Impact Tester – 150J, 300J or 450J. The Class G is engineered for impact testing of metals with the principle of a combined system for Charpy and Izod impact testing. The device is equipped with an impact force sensor placed inside the striker.

Tensile test for fine wires/foils . Charpy V notch Impact Test (a) R. T. inclusive of sample machining charges as per ASTM E23 (for a total set of 3 specimens and 3 readings) Impact Test above and below 60°C. Rockwell Hardness tester (scale A, B, C ) Vickers Hardness tester (Micro/Macro indentation) In general, delamination occurs as a result of brittle fracture; however, an increase in toughness in the Charpy impact test can be provoked. This mechanism is called thin sheet toughening or delamination toughening. . The samples for EBSD investigations were prepared by mechanically grinding and polishing followed by an electrolytic . Temperatura: Las propiedades de tenacidad de un material pueden variar con la temperatura. Algunos materiales pueden volverse más frágiles a temperaturas bajas. Procesamiento térmico: Los tratamientos térmicos, como el temple y el revenido, pueden alterar las propiedades de tenacidad del material. Conclusión. La prueba de impacto Charpy es una .The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, Instron Ceast 9050 impact tester, and microscope. It also outlines the step-by-step procedure for setting up and performing an impact test, which .

Izod impact tests are used for characterization of the impact strength of a plastic or composite material at high strain rates. The flexural impact stress is applied to a notched or unnotched specimen gripped on one side, with dimensions 10 x 4 x 80 mm. Tests according to the Izod and Charpy method deliver similar conclusions about the impact strength of a material.

charpy impact testing procedure

charpy impact testing methods

charpy impact test sample

Há 30 anos, Maurício Zardeto realizava o sonho de abrir uma lanchonete em Cianorte. Com dedicação, qualidade e tradição, o Hamburgão Lanches conquistou o.

charpy impact test grinding|charpy impact test calculation table